Effective. Innovative. ERMAFA.

Mechanical engineering

Mechanical engineering

As unique as your company

Our portfolio:

machines and systems

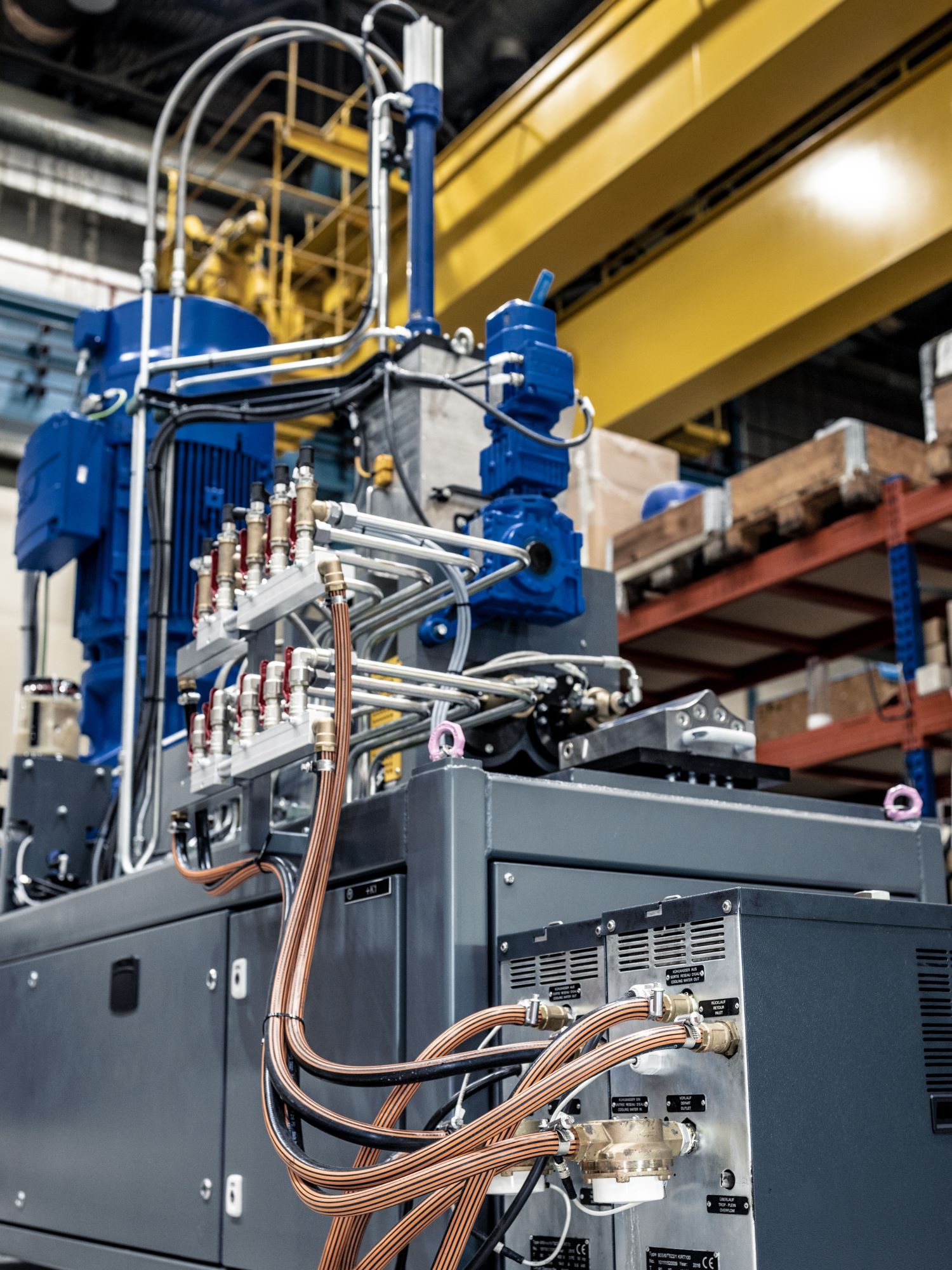

Processing machines for the plastics industry

From the processing of thermoplastics (PE, PP, PA, PVC, etc.) and elastomers (NR, NBR, EPDM, FKM, etc.) to recycling - we design the right machines and systems, individually tailored to your specific applications.

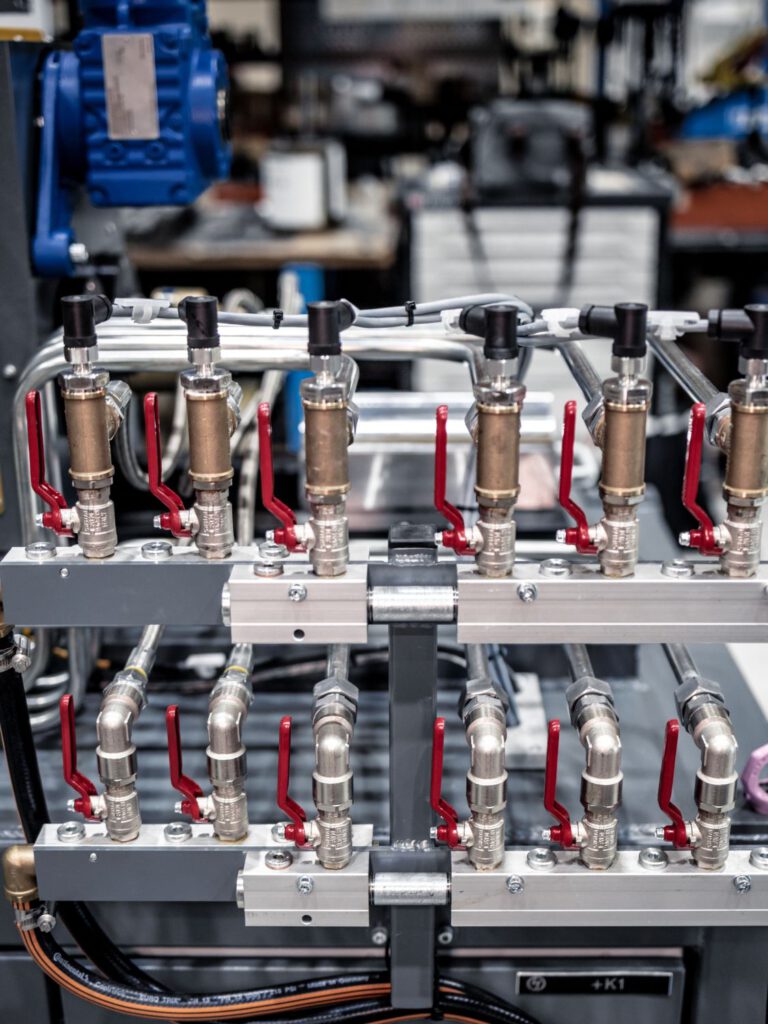

Special machines and systems

Development, design and production of customized solutions for specific applications and processes

Automation of your production line

Gain a competitive edge with the automation of your production line and increase the efficiency and effectiveness of your systems

Mechanical production

diverse and efficient processing methods on 3600 m2

Plant engineering

Plant engineering in the best hands

By using tailor-made process solutions, you can optimize your processes and thus increase productivity and reduce costs. We solve your challenges with individual designs and automation of production sections or entire systems.

Project planning

Individually planned!

Based on your ideas, together we will find the optimum solution for you!

Construction

We design machines or complete systems according to your specific functional requirements.

Realization

Thanks to our diverse process technologies and our wealth of experience, we implement plans quickly.

Maintenance

Modern sensor technology allows predictive maintenance to find its way into your workshop.

Follow us on

Social Media

Other divisions

Mechanical production

In our in-house production facility, we machine components in individual or series production. With our extensive range of machinery, we can machine all machinable materials up to 20 tons.

Environmental technologies

Sustainable resource management is a very present topic in the industry. Some of our sister companies deal exclusively with green technologies and the circular economy.

Plastics and rubber industry

FROM CREATION TO RECYCLING

For the plastics, rubber and elastomer processing industries, we cover the entire life cycle of a rubber product (e.g. tires) or plastic product with our portfolio of standard machines and individual special machines - from the multi-stage mixing process to fully automated recycling systems.

Whether you work in tire manufacturing, plastics, the automotive industry or recycling, we have the solutions to meet your requirements.

About us

Precision in tradition

Our long tradition of mechanical engineering underlines one thing above all:

Our expertise in this area.

Using the best design and development methods, we offer high-quality products and services - and have been doing so since 1837 - in the field of special machines and for another 80 years in the field of machine tools.

Both nationally and internationally, we have a number of important projects to show!

> 180

Years of experience

2

Locations

> 90

Employees

What characterizes a special machine?

Specific problem solutions with special machines

A special machine in mechanical engineering is a customized machine developed and manufactured specifically for certain applications or requirements. In contrast to standard machines, which are suitable for a wide range of applications, special machines are designed to solve specific problems or challenges in a particular industry or production situation.

Special machines are usually produced as one-offs or in small series. They can perform a variety of tasks, from automating production processes to overcoming specific engineering challenges.

Special machines can be used in various industries, including automotive, food and beverage, pharmaceutical, packaging and even medical technology.

The design of a special machine requires close cooperation between customers and mechanical engineers. The customer's specific requirements, desired functions and special requests are taken into account. The mechanical engineers then develop customized solutions to meet these requirements. This includes the selection of suitable components, the design of machine structures and the integration of various systems and controls.

The advantage of special machines lies in their ability to meet specific requirements and offer customized solutions for complex tasks. They can increase productivity, optimize processes, improve quality and make working conditions safer for operators.

Our program includes all solutions tailored to customer requirements - from the project planning of individual machines to the delivery and assembly of complete systems.