Internal mixer & stamp mixer

Internal mixer & stamp mixer

for homogeneous mixtures of rubber and caoutchouc

Suitable solutions from basic mixing to multi-stage mixing applications

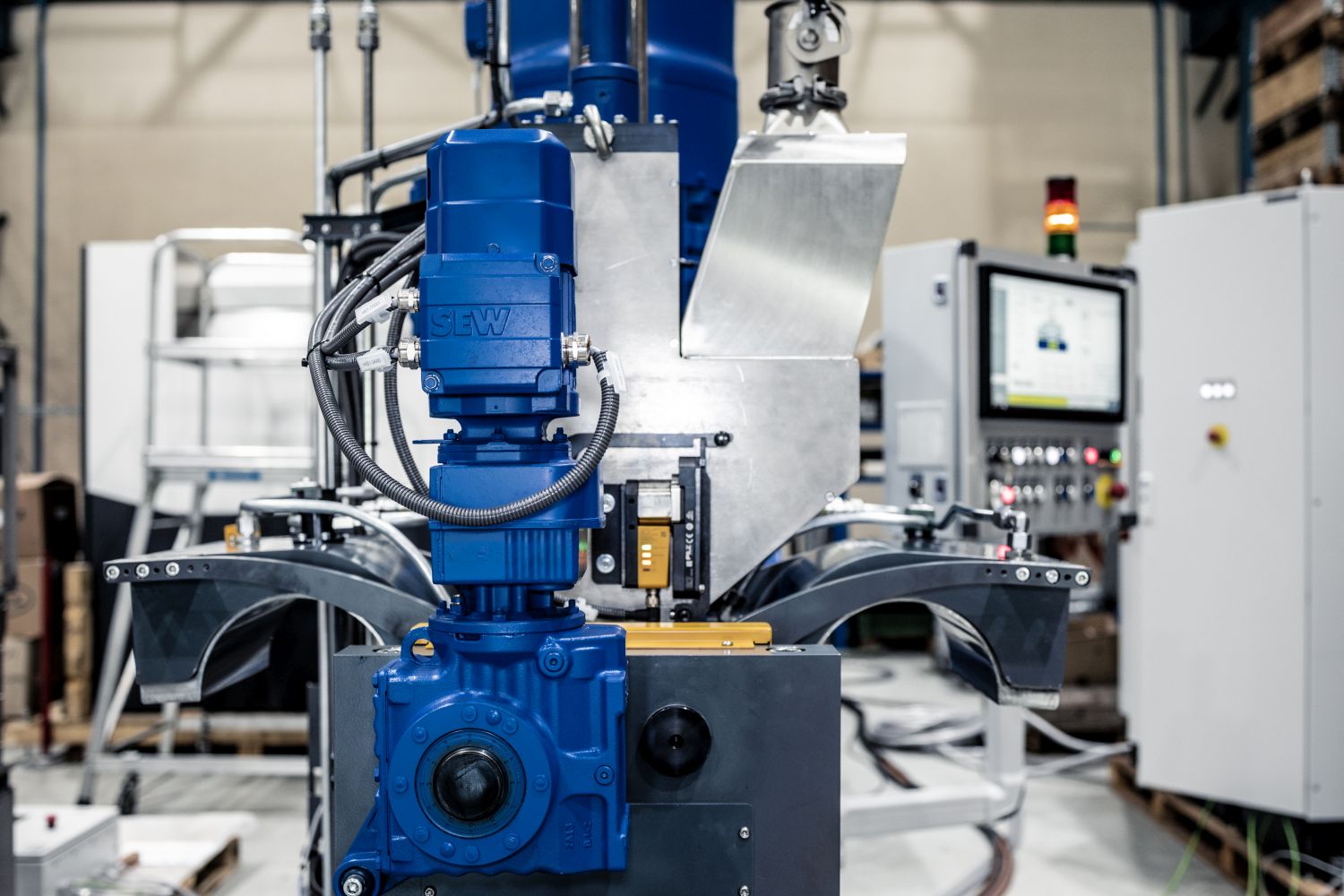

Sophisticated internal mixers for rubber and plastics processing

We have been successfully developing our machines continuously for years, with the drive to always exceed the current requirements of the industry, in particular rubber processing, and to recognize and improve existing potential.

Our internal mixers are ideal for the tire and rubber industry in particular, as they use rotating kneading tools to homogeneously mix all compound components. Intuitive operation and safety in the workplace are just as important to us as resource-saving production and efficient processes.

We distinguish between 2 basic categories of internal mixers:

Laboratory internal mixer

Industrial internal mixer

Laboratory internal mixers and industrial internal mixers are both devices for mixing and homogenizing materials. They work in a similar way by intensively mixing inherent materials in a closed chamber by means of tangential or intermeshing rotors.

While laboratory internal mixers are used to develop and optimize mixtures and test processes, industrial internal mixers are designed to implement these results in mass production.

Despite their similar functionality, they differ in some important respects:

➝ Laboratory interior mixer:

They are often equipped with advanced control and measurement systems to ensure precise conditions during the mixing process and to collect and optionally record data for research and development.

➝ Industrial internal mixer:

They are designed for continuous production and the mixing of large quantities of materials, whereby the parameters determined at laboratory level are scaled up.

➝ Laboratory interior mixer:

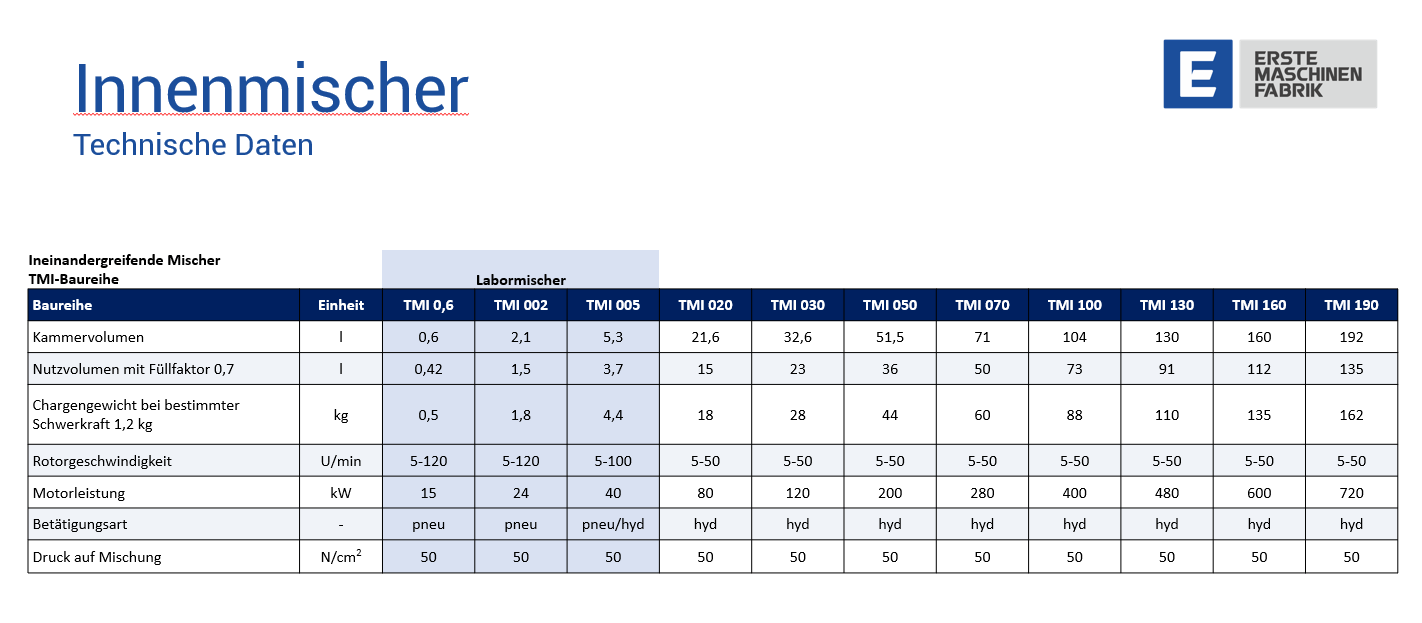

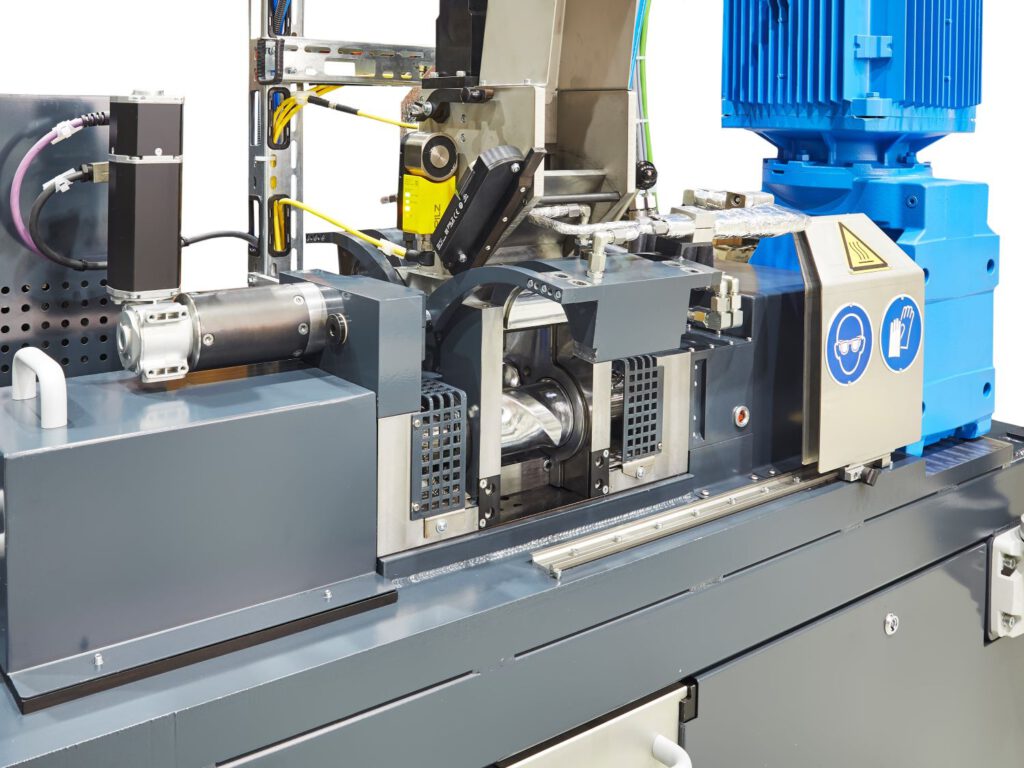

They are typically smaller and designed for R&D purposes (research and development). The capacity is in the range of 0.6 - 5 liters, which enables small batches and experiments.

➝ Industrial internal mixer:

These are designed for large-scale production and therefore have a much greater capacity. They can process several hundred kilograms per batch (see details), depending on the specific model and production requirements.

➝ Laboratory interior mixer:

They are often equipped with advanced control and measurement systems to ensure precise conditions during the mixing process and to collect and optionally record data for research and development.

➝ Industrial internal mixer:

Although they may also have advanced control systems, they are primarily focused on efficiency, reliability and throughput.

➝ Laboratory interior mixer:

They are generally more flexible when it comes to adjusting process parameters in order to test a wide variety of materials and recipes.

➝ Industrial internal mixer:

The focus here is more on the consistency of the process in order to guarantee standardized products.

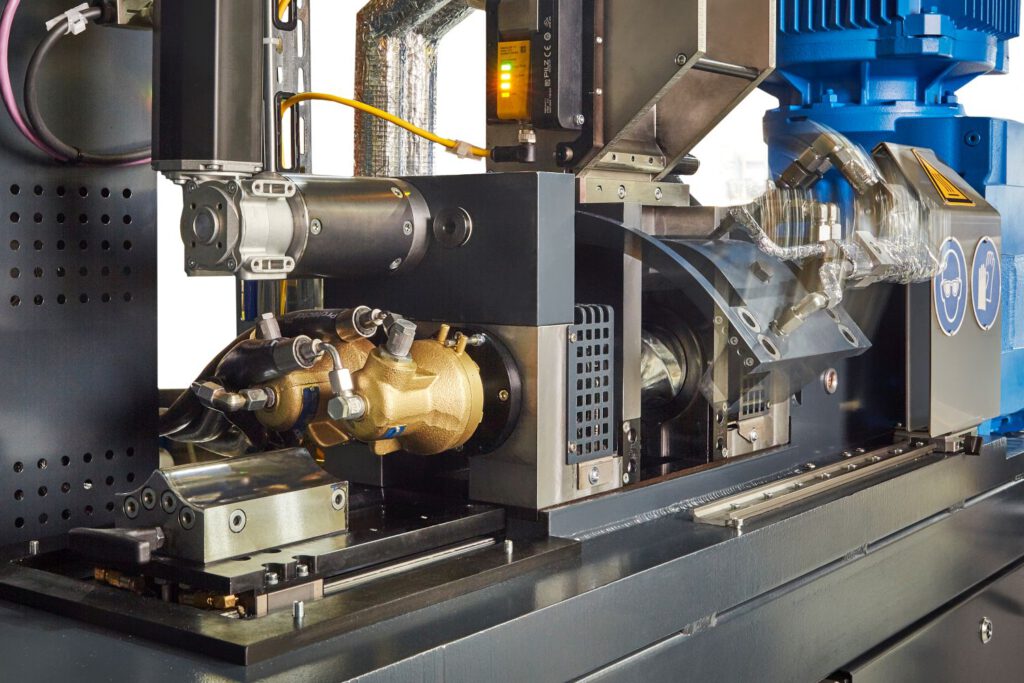

Details about our laboratory mixers

- adapted to the volume requirements for development: 0.6 liters, 2 liters, 5 liters

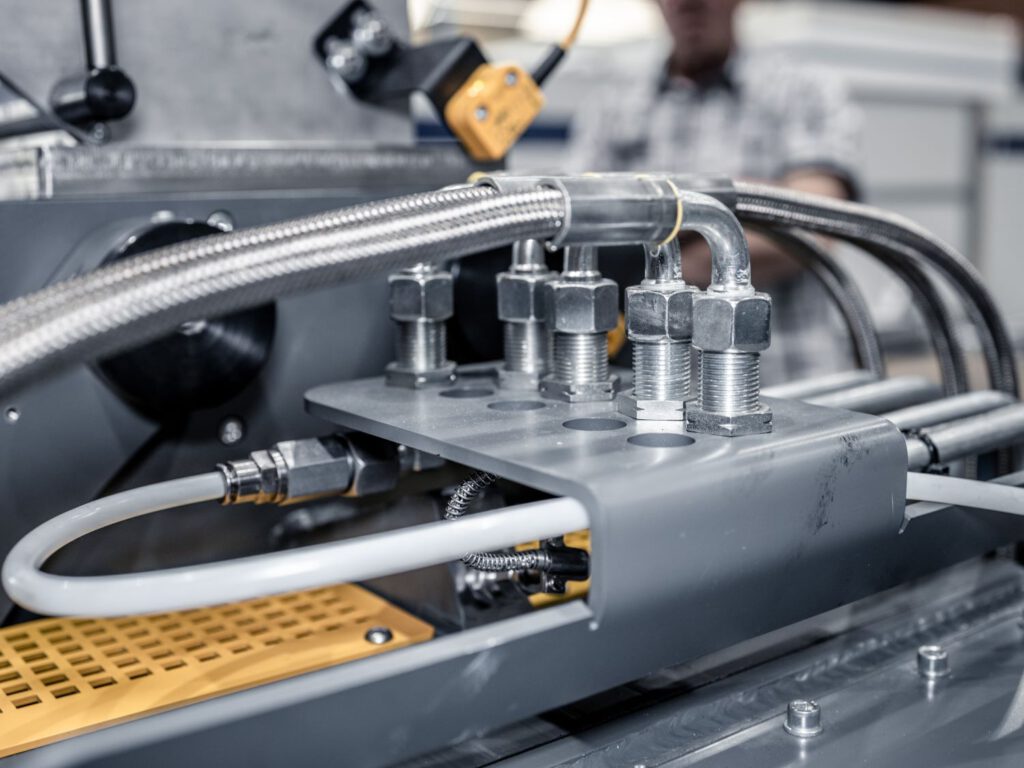

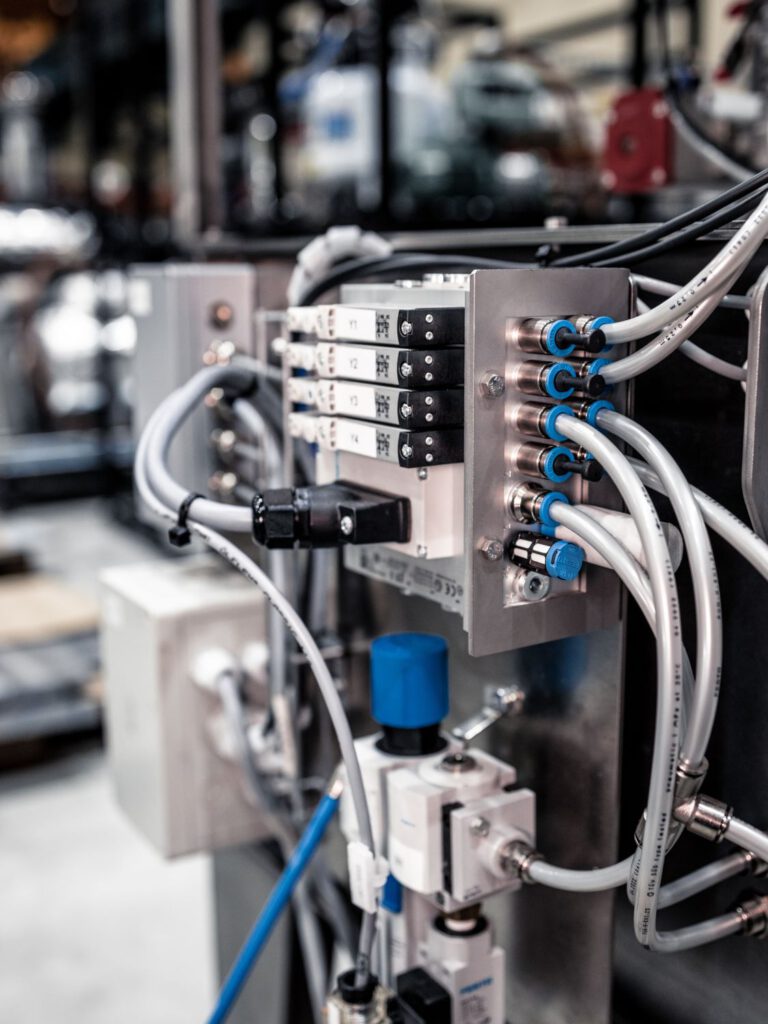

- Adapted to installation in a laboratory environment: extremely compact, integration of pneumatic or hydraulic controls

- adapted to manual loading: Machine ergonomically adapted for manual filling and emptying

- Software adapted to the extremely diverse and different mixtures: Mixing recipes/mixing process freely programmable, access to all relevant parameters

- Mixer design adapted for very good, easy cleaning: hinged trough, cleaning position for the saddle and plunger

- Safety adapted to manual work: fluid working possible despite comprehensive safety in accordance with current standards / guidelines

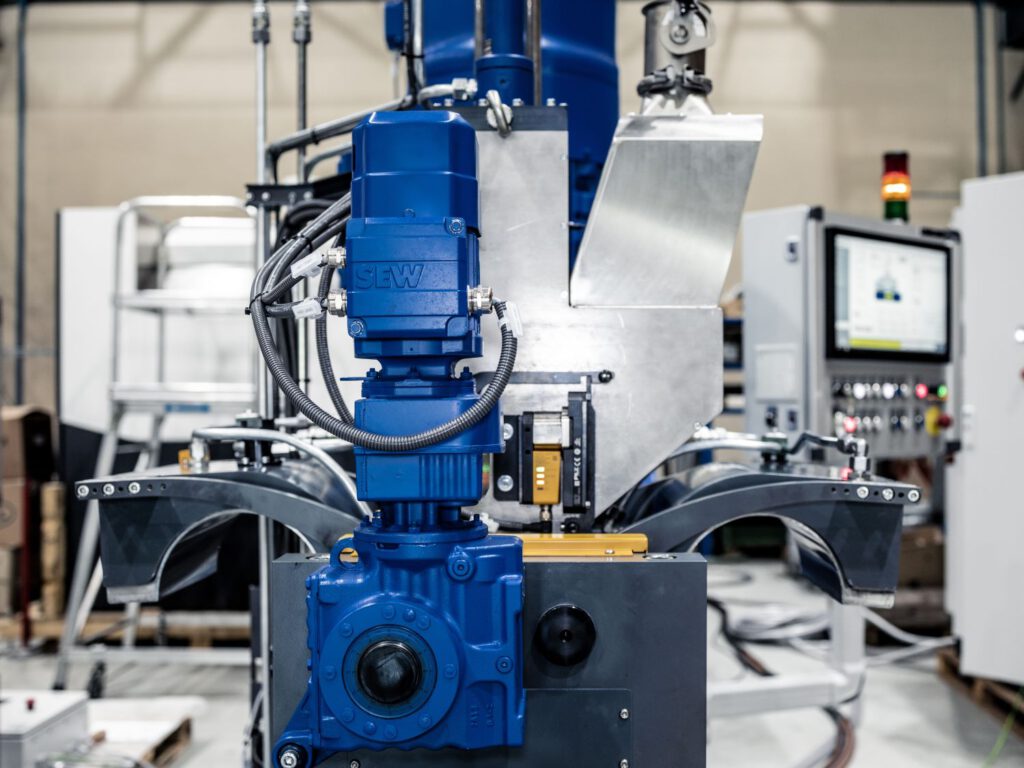

- State of the art components

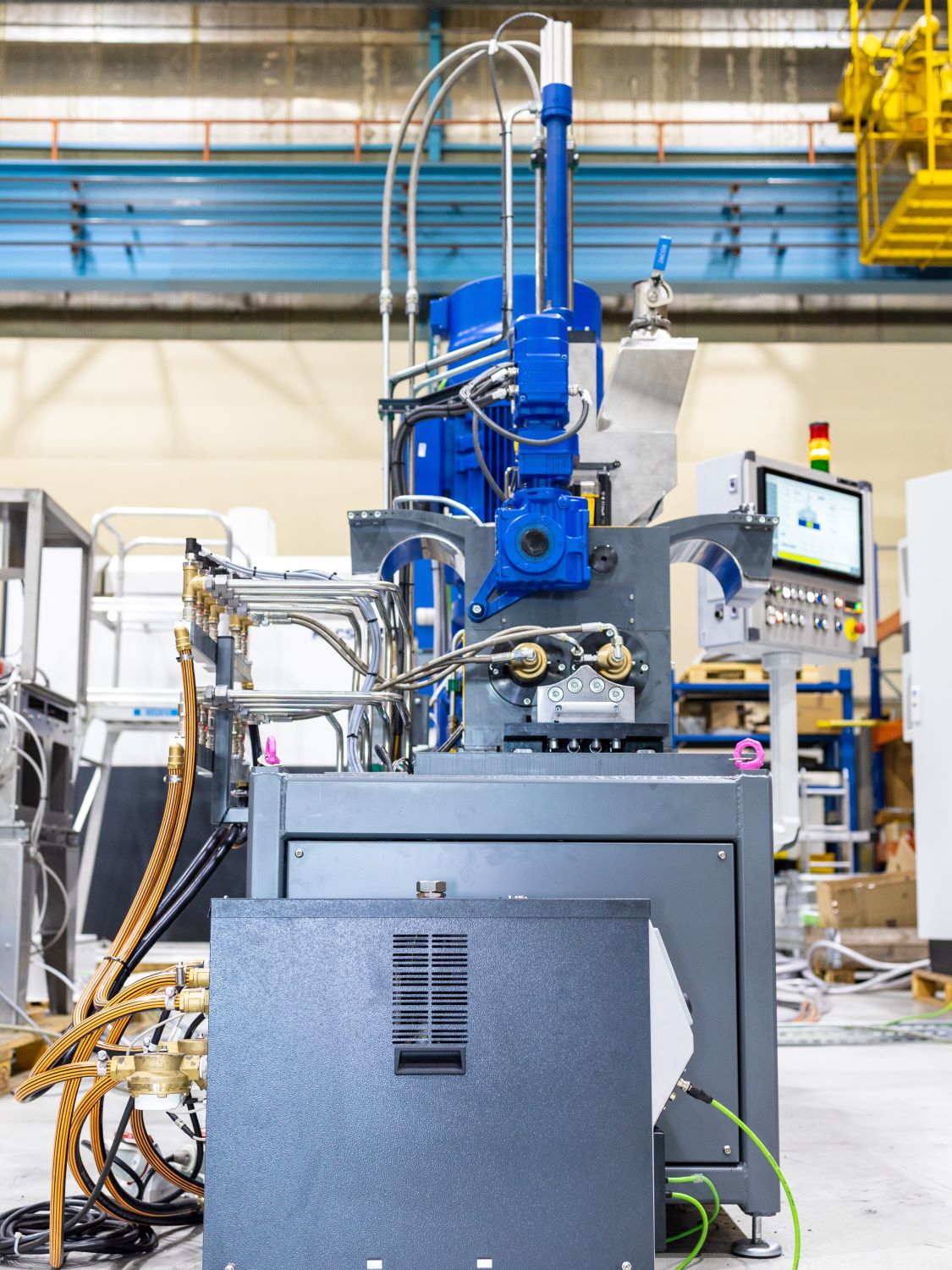

Details on our industrial mixers:

- Volume for industrial requirements: from 30 liters (see download for details)

- Modular design for effective installation and maintenance

- Optimized for automated assembly

- Optimized for throughput

- Easy cleaning

Do they have special requirements?

Please feel free to contact us!

Your contact person: