Service

Our service - your advantage

ERMAFA:

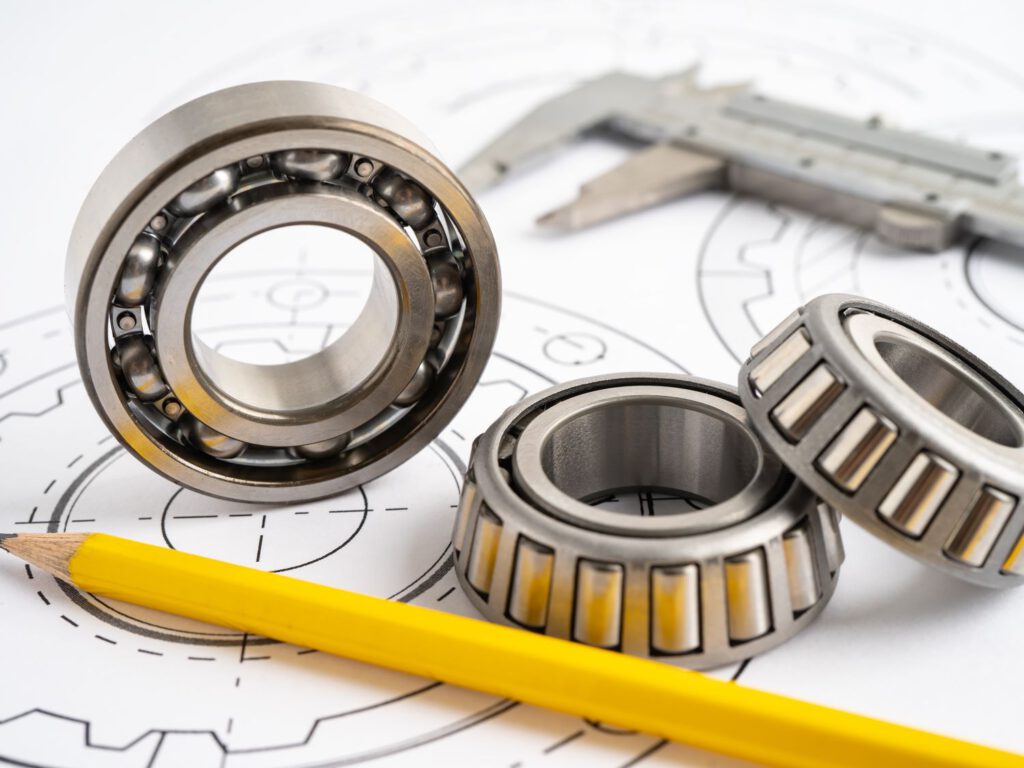

Your partner for comprehensive service in manufacturing

At ERMAFA, service is at the heart of everything we do. We know that your projects are often unique and complex. That's why we offer you comprehensive services that go far beyond mere production. Our aim is to provide you with expert support at every stage of your project and to offer customized solutions.

Advice and planning

A successful project begins with thorough planning. Our experienced engineers and technicians are on hand to advise you right from the planning phase. We analyze your requirements and work with you to develop the optimum production solutions. We attach particular importance to this:

- Individual advice: We take the time to understand your specific needs and requirements in detail.

- Feasibility studies: We use detailed analyses and simulations to check the feasibility of your projects.

- Process optimization: We identify potential savings and optimize your production processes for maximum efficiency and quality.

Prototype production

From the idea to the prototype - we accompany you through the entire development process. Our modern production technologies enable the fast and precise production of prototypes that meet your expectations and provide a solid basis for series production. Our services in this area include

- Fast implementation: Thanks to our flexible machinery, we can realize your prototypes in the shortest possible time.

- High precision: We use the latest CNC technology to manufacture your prototypes with maximum precision.

- Variety of materials: We work with a wide range of materials to meet your specific requirements.

Series production

For series production, we offer you customized solutions that are tailored to your production requirements. We guarantee the consistently high quality of your components and assemblies - regardless of the quantity. Our services include

- High flexibility: We adapt our production capacities flexibly to your needs.

- Efficient production: Optimized production processes and state-of-the-art machinery ensure cost-efficient series production.

- Quality assurance: Each part undergoes strict quality controls to ensure compliance with your specifications.

Post-processing and finishing

In addition to mechanical production, we offer extensive post-processing and finishing services. These include

- Surface treatment: We offer various processes such as painting, electroplating or anodizing to improve the surface quality and durability of your products.

- Installation and assembly: We take on the installation of assemblies and complete systems so that you receive a finished product from a single source.

- Logistics and shipping: Our service does not end with production - we also take care of the secure packaging and reliable shipping of your products.

Maintenance and repair

We don't leave you alone after production either. Our maintenance and repair service ensures that your machines and components always remain ready for use. We offer:

- Regular maintenance: We increase the service life of your machines and components through preventive maintenance measures.

- Fast repairs: In the event of a defect, we respond quickly and reliably to minimize downtime.

- Spare parts service: We keep a large selection of spare parts in stock and manufacture special parts to your specifications.

Your expert for comprehensive service

Our services are designed to provide you with the best possible support - from the initial consultation to the delivery of the finished product and beyond. Rely on ERMAFA as your partner for mechanical manufacturing and benefit from our comprehensive know-how and our commitment to quality and customer satisfaction.

Your contact person: