Automation

Increased efficiency and future viability

Increasing productivity through innovative automation

Cost reduction

Reduce your production costs.

Quality improvement

Increase the quality of your products.

Flexibility

Adapt your production processes quickly to changing requirements.

Increased efficiency

Features: Optimized processes, shorter throughput times, higher productivity

Benefits: Cost reduction, increased capacity, faster time to market

Customer benefits: Fast order processing, on-time deliveries, improved supply chains

Cost reduction

Features: Automation of routine tasks, reduced manpower requirements, less waste

Advantages: Reduction in production costs, higher profitability, competitive advantage

Customer benefits: Attractive prices, cost-effective solutions

Quality improvement

Features: Higher precision, consistent results, improved product quality

Benefits: Reduction of errors, increased customer satisfaction, strengthening of the brand

Customer benefits: Reliable products, long service life, fulfillment of high quality standards

Flexibility and adaptability

Features: Scalable systems, modular solutions, rapid adaptation to changing requirements

Advantages: Fast response to market developments, individual customer solutions, future-proof

Customer benefits: Customized solutions, fast response to new requirements

Occupational safety and ergonomics

Characteristics: Protection against hazards, ergonomic workplaces, avoidance of physical strain

Advantages: Healthy and motivated employees, less downtime, positive working atmosphere

Customer benefits: Responsible corporate image, contribution to the health of your employees

Possibilities

Individual workstation solutions: Efficient and customized solutions for assembly, joining and handling processes at individual workstations to optimize production processes.

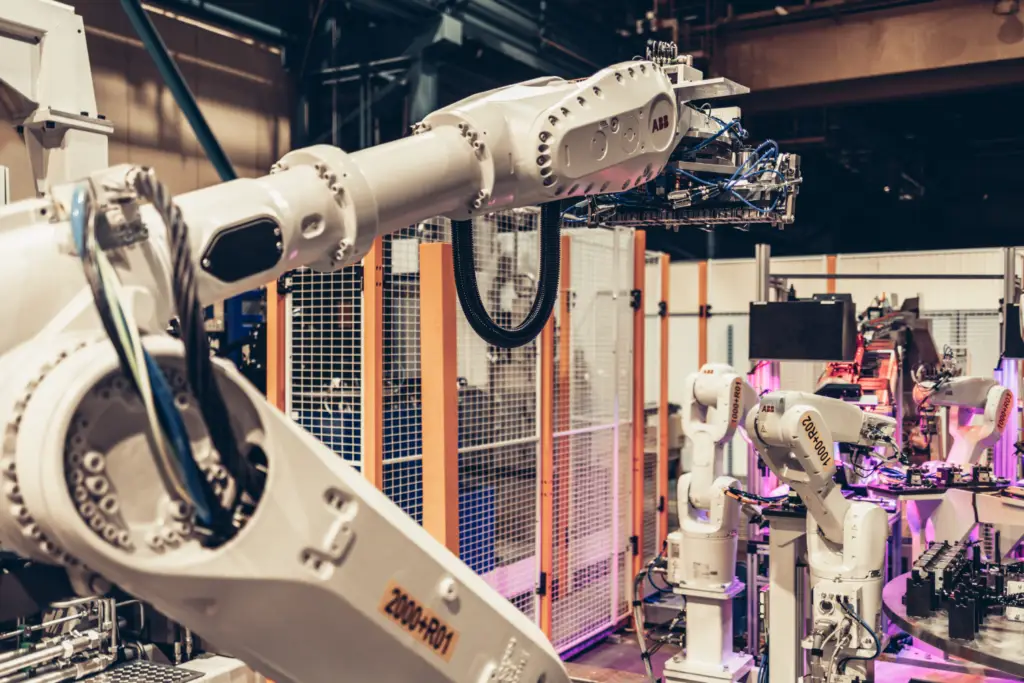

Robot cells: State-of-the-art robot cells for a wide range of applications such as assembly, welding, component handling or measuring processes - precise and flexible for the most diverse requirements.

Turnkey solutions: Comprehensive turnkey solutions that cover all aspects of your production. From parts infeed and outfeed to testing and measuring systems to labeling systems, handling and assembly robots and fixtures to processing machines - everything from a single source for maximum efficiency.

Example of automation in production: camshaft systems

Our automated camshaft systems represent the pinnacle of modern manufacturing technology, specifically designed to ensure maximum efficiency and precision. Here are the outstanding features:

Precise production: Through advanced automation technology, we achieve precise manufacturing of every camshaft. Each machining step is carried out with the highest accuracy to exceed quality standards.

Increased efficiency: Our automated systems optimize the entire production process by focusing on speed and efficiency. The resulting short cycle times lead to a significant increase in overall efficiency.

Cost savings: Investing in our automated camshaft systems leads to long-term cost savings. Reduced personnel costs, minimized reject rates and more effective use of resources contribute to the profitability of your production.

Flexibility and adaptability: Our systems offer the flexibility to adapt to changing production requirements. They can be easily converted to new product lines or special requirements.

Quality assurance: Automated testing and measuring processes ensure that every camshaft meets the highest quality standards. Early fault detection and correction guarantee consistently high product quality.

Are you interested in

- Single workstation solutions

- Robot cells

- Turnkey solutions

We will be happy to advise you on individual solutions tailored to your needs. Please do not hesitate to contact us.