Special machine construction projects

Special machinery projects

Complexity and individual concepts combined

Special machinery projects are characterized by their complexity and individual design. Special machines offer specially developed solutions for specific customer tasks - often accompanied by the automation of parts or units.

High performance even without a foundation

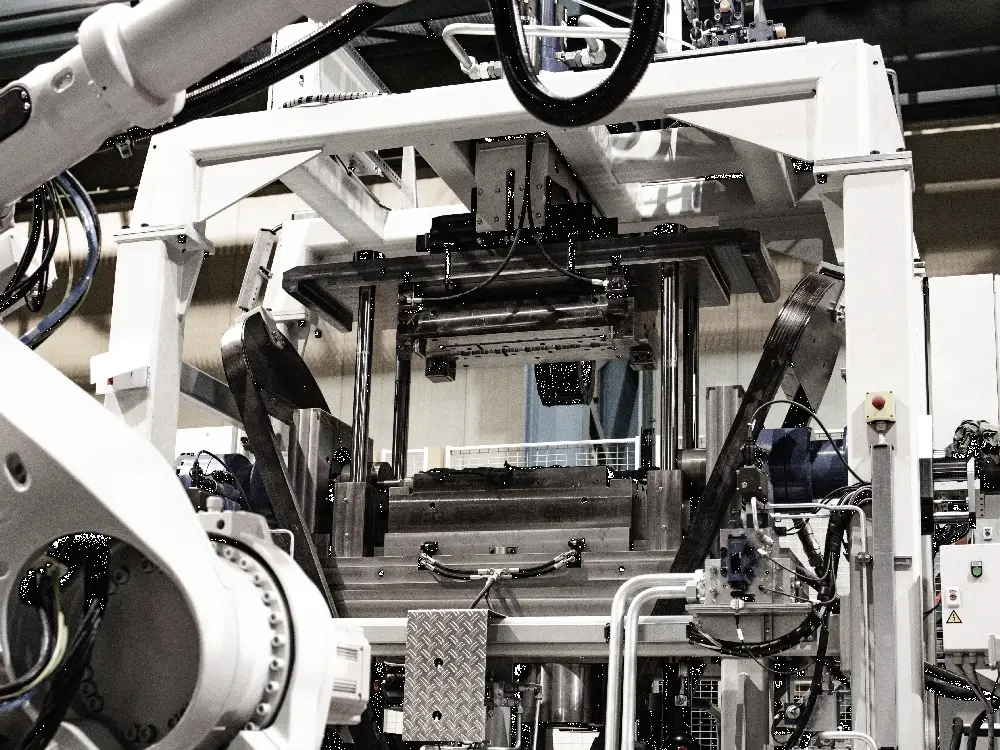

Hydraulic lightweight press

We were able to develop a special innovation in the field of forming together with IWC. The result was a hydraulic press that requires neither a foundation nor a basement.

This crucial aspect minimizes space requirements, improves the arrangement of machines and enables efficient workspace design. The quick installation without a foundation shortens the commissioning time and promotes a rapid start to production. The flexibility of location without a fixed foundation makes it easy to adapt the machine.

Unlike conventional hydraulic presses, we provide you with individual sizes designed for your specific applications. This minimizes the space required in the workshop and reduces both acquisition and running costs.

- Low maintenance and servicing costs, quick tool change

- Expansion of the market segment for formed parts through small batch sizes

- Low overall height, less space required

- Integration into assembly lines or other process chains possible

Potential

Load-bearing lightweight components using the UD tape process

UD tape system

UD tapes are continuous fiber-reinforced tapes with a thermoplastic matrix.

The product is thermoplastically moldable, lightweight and yet resilient.

The glass or carbon fibers of the UD tape are unidirectional and can be processed into multilayer components using pressing or thermal processes.

The tapes are manufactured using the patented direct impregnation process, which achieves a high degree of impregnation and a good bond between the fibers and the matrix material. The fiber content of the tapes can be flexibly adjusted for different areas of application.

In further process steps, the UD tape can be used to produce organic sheets and molded parts.

Potential

- High load-bearing capacity thanks to multiple layers

- Low component weight

- Suitability for thermoforming

- Higher recycling potential through thermoset solutions, for example

These autoclaves for the treatment of contaminated waste provide enormous economic added value! Cross-contamination is eliminated through direct on-site treatment - which is safe for people and the environment.

In addition, cost-intensive transportation of hazardous goods is no longer necessary, which represents an enormous CO² saving potential.

Up to Safety Insurance Level SAL= 10high48 (WHO recommends 10-6)high10

Safe treatment of infectious and hazardous waste

MACS - Machine Autoclave Cutting Sterilization

- On-site solution or industrial solution

- Customized design according to application

- Simple operating software

- Solids and liquid waste